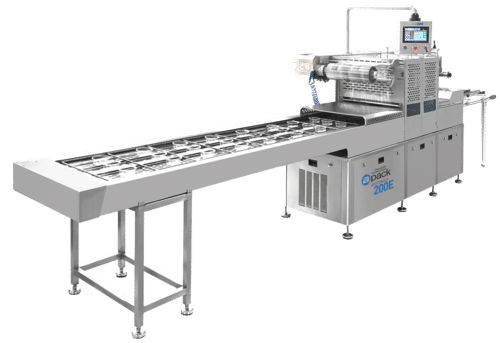

butter- Tray Sealer ( AutoMAP 200e)

3500000 INR/Unit

Product Details:

X

butter- Tray Sealer ( AutoMAP 200e) Price And Quantity

- 1 Unit

- 3500000 INR/Unit

Product Description

| CREATIVE PACKAGING SYSTEMS | |||

| AutoMAP 200e | |||

| CERTIFIED WORLD INDUSTRY STANDARDS | |||

| LOWER COST FOR INDUSTRIAL PRODUCERS | |||

| HIGH-END QUALITY COMPONENTS | |||

| FULLY AUTOMATIC | |||

| COMPATIBLE REMOTE ACCESS VIA INTERNET | |||

| EASY TO USE | |||

| EFFECTIVE / VARIABLE / PROFITABLE | |||

| VACUUM PUMP IS INSIDE THE FRAME | |||

| GRADUAL VACUUM APPLICATION | |||

| HIGH PERFORMANCE MAPPING UNIT | |||

| FITS IN SMALL AREAS | |||

| COMPATIBLE FOR ALL TYPE OF PACKAGING ACCESSORIES | |||

| WORK WITH ALL TYPE OF TRAY AND FLEXIBLE FILM | |||

| WORK WITH PRINTED TRAYS AND FILMS | |||

| TOOL SET (MOULD) CHANGEABLE | |||

| CONVENIENT FOR FOOD PACKAGING | |||

| Key components of a tray sealing machine include: | |||

| Tray placement mechanism: This part of the machine holds the empty trays or containers in place, ensuring they are correctly positioned for the sealing process. | |||

| Filling system: Some machines come equipped with a filling system that accurately dispenses the product into the trays before sealing. | |||

| Film or lidding material roll holder: The machine holds and dispenses the film or lidding material that will be used to seal the trays. | |||

| Sealing station: The sealing station applies heat and pressure to the film, causing it to conform to the contours of the tray's rim and create a secure seal. | |||

| Cutting mechanism: If the machine uses a roll of film instead of pre-cut lidding, it will have a cutting mechanism to separate the sealed trays. | |||

| Control panel: The control panel allows the operator to set parameters such as sealing time, temperature, and pressure. | |||

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Special Machines' category

|

CPS CREATIVE PACKAGING SYSTEMS PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send SMS

Send SMS